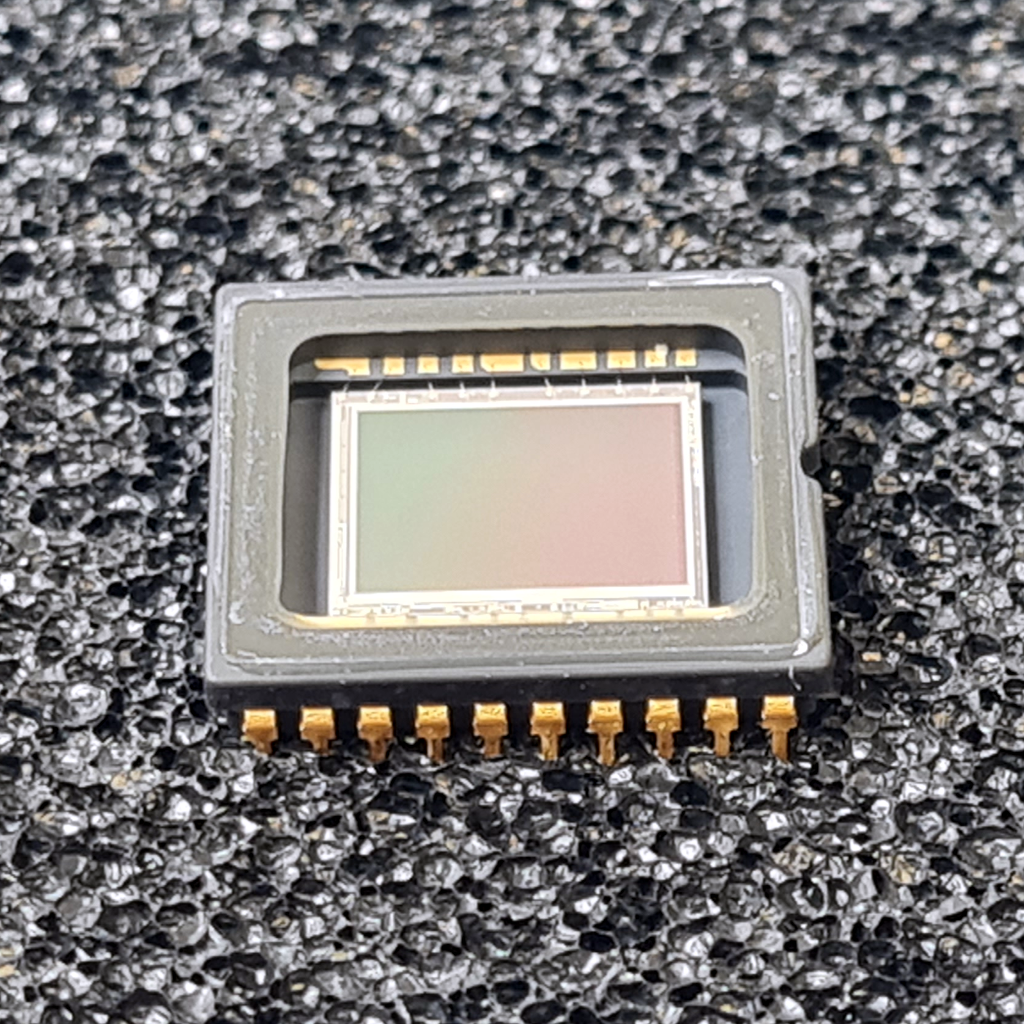

Area sensors based on CCD or CMOS are at the heart of many high-precision image processing systems. However, the cover glass installed at the factory can significantly limit the performance of the sensor in certain applications. With our specialized cover glass removal, we optimize the optical properties of the sensor and enable higher light sensitivity, improved spectral transmission and minimized reflections—essential for research, industry and science.

The cover glass originally serves as a protective layer for the sensor. However, in many applications it can cause unwanted interference, reflections or spectral limitations. Especially in areas where maximum quantum efficiency, highest contrast fidelity or exact spectral detection is required, a sensor without cover glass offers clear advantages:

In addition to cover glass removal, Eureca also offers the application of filters as a service. Furthermore, a UV coating can also be applied to a de-windowed sensor in order to extend the spectral range.

Our controlled removal method guarantees that the cover glass is removed from the sensor without mechanical or thermal stress. As a result, the pixel structure remains unchanged and the full performance of the sensor is retained.

Are you interested in a customized solution? Contact us for a personal consultation on cover glass removal and sensor optimization!

Do you use CCD/CMOS linear sensors or SWIR detectors instead of area sensors? We also have suitable processes for cover glass removal in our program.

Here you can easily ask a question or inquiry about our products:

Last update: 2025-08-05