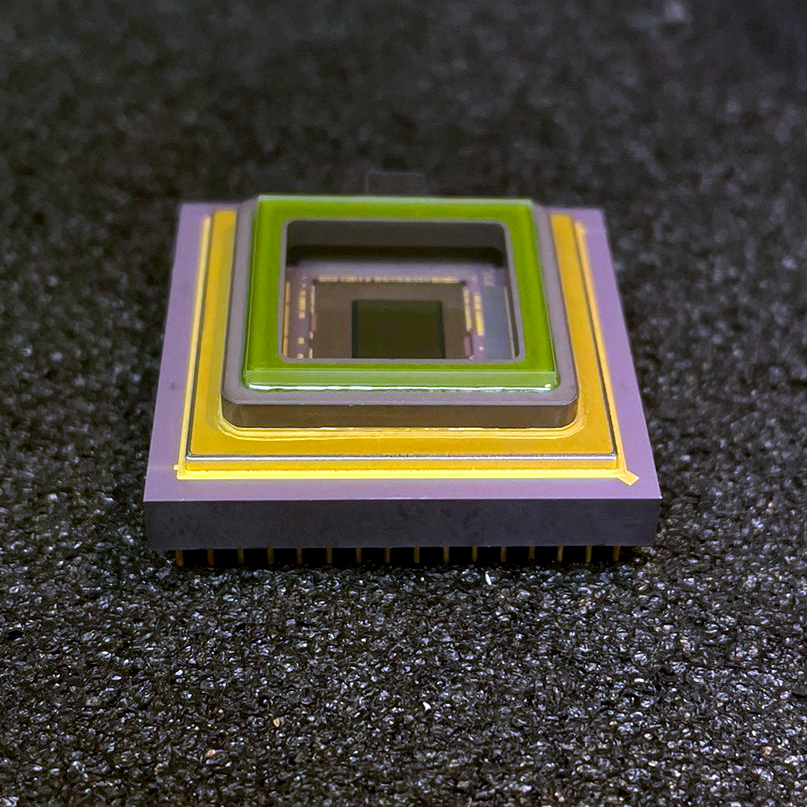

We are pleased to announce that our professional cover glass removal for image sensors is now also available for the Sony SWIR sensors IMX990 and IMX991! With this we offer a customized solution for applications requiring highest precision and unlimited sensitivity in the VIS and SWIR range (400 – 1700 nm).

Many applications in the SWIR range benefit from a cover glass removed on the sensor side, as this

By removing the cover glass, the performance of SWIR sensors is optimized in the following areas:

Our cover glass removal ensures that your sensor achieves the best possible performance in your specific application.

Want to learn more? Contact us for details or customization!

The IMX990 and IMX991 SWIR sensors from Sony are based on SenSWIR technology and are used for a wide range of demanding applications. Their special feature is that they are sensitive both in the visible range (VIS) and in the short-wave infrared range (SWIR, 400 – 1700 nm).

The sensors are particularly interesting because they work with CMOS technology, which makes them more compact, energy-efficient and cost-effective than classic InGaAs sensors.

Here you can easily ask a question or inquiry about our products:

Last update: 2025-04-03