For assessing the resolution capabilities of, for example, optics and cameras, we offer test targets on which test structures with different resolutions are present. Two versions are currently available as standard.

Compared to similar products from competitors, Eureca's test targets are characterized by the fact that they can be manufactured on paper or film according to individual requirements, which is not offered to the same extent by most competitors. There is also the advantage of being able to choose between baryt paper and transparent film. This means that Eureca offers a variety of materials that are suitable for many different applications and preferences.

New in the portfolio are particularly large Siemens stars on a film basis, which are also suitable for testing optics over greater distances due to their size of 90 × 90 cm. The resolutions range from 0.015 lp/mm up to 25 lp/mm

| Type | Beams | Resolution | Size | Material |

|---|---|---|---|---|

| Siemensstern-450-Baryt | 450 | 1 – 25 lp/mm | 20 × 20 cm | Baryt paper 255 g |

| Siemensstern-450-Film | 450 | 1 – 25 lp/mm | 20 × 20 cm | Transparent film |

| Siemensstern-360-Film-highres | 360 | 0.6 – 25 lp/mm | 20 × 20 cm | Transparent film |

| Siemensstern-36-Film | 36 | 0.06 – >10 lp/mm | 20 × 20 cm | Transparent film |

| Siemensstern-large-360-Film-highres | 360 | 0.15 – 25 lp/mm | 63 × 75 cm | Transparent film |

| Siemensstern-large-36-Film | 36 | 0.015 – > 10 lp/mm | 63 × 75 cm | Transparent film |

| Siemensstern-360-Glas-veryhighres | 360 | 6 – 250 lp/mm | 20 × 20 mm | AR chrome on glass |

| Siemensstern-36-Glas-highres | 36 | 0.6 – >100 lp/mm | 20 × 20 mm | AR chrome on glass |

| Siemensstern-huge-360-Film-highresNEW! | 360 | 0.1 – 25 lp/mm | 90 × 90 cm | Transparent film |

| Siemensstern-huge-36-FilmNEW! | 36 | 0.01 – > 10 lp/mm | 90 × 90 cm | Transparent film |

| Pocket-Siemensstern-360-Film-highresNEW! | 360 | 1 – 25 lp/mm | 10 × 10 cm | Transparent film |

| Pocket-Siemensstern-36-FilmNEW! | 36 | 0.1 – > 10 lp/mm | 10 × 10 cm | Transparent film |

| Siemensstern-ArrayNEW! | 36 & 360 | 0.5 – > 25 lp/mm | 30 × 20 cm | Transparent film |

| USAF-1951-Baryt | 0.0625 – 28.5 lp/mm | 20 × 20 cm | Baryt paper 255 g | |

| USAF-1951-Film | 0.0625 – 28.5 lp/mm | 20 × 20 cm | Transparent film | |

| Chromatische-Aberration-Test-ChartNEW! | 20 × 20 cm | Transparent film | ||

| Test-Target-DistortionNEW! | 20 × 20 cm | Transparent film |

Eureca's test targets are used in a wide range of applications:

The Siemens star was developed by Siemens AG (then Siemens & Halske AG) in the 1930s. With this test pattern, the quality of optical imaging systems can be checked.

Digital photo of the Siemens star on foil on a light table

To show how the Siemens star works, we have calculated images with HDTV resolution (i.e. 1920 × 1080 pixels, reduced to 1080 × 1080) and various levels of blurring.

With 1080 pixels and an image height of 20 cm, that is 137.16 ppi or 0.185 mm/pix. Nyquist is thus 2.7 LP/mm for monochrome and 1.35 LP/mm for color (Bayer pattern).

At higher spatial frequencies of the template, moirés occur as a result of oversampling, which can lead to problems with the evaluation, especially in machine vision applications. For metrological purposes, it is therefore often helpful to use a reasonable amount of well-defined blur.

In order to make the differences between the various blurs clear, we show composite images here (one monochrome, one color):

It is important that the targets are only viewed on the monitor in 1:1 mode (click for original view), as each scaling produces additional artifacts! This type of calculation has already been well tested at Eureca and has been verified several times by practical recordings with real lenses under real conditions.

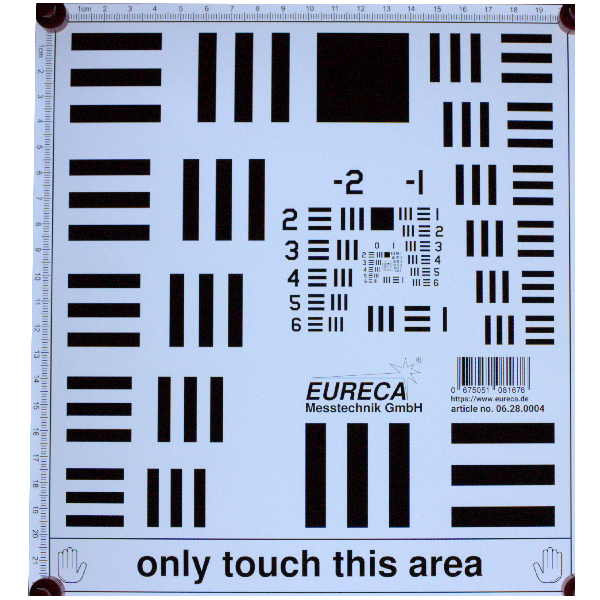

This test chart was designed by the United States Air Force (USAF) in 1951 to check the resolution of aerial cameras and other optical instruments.

Digital photo of the test image on foil on a light table

The test targets are manufactured internally at Eureca. Customized versions on paper or film, with test structures individually tailored to the respective measurement task, are also possible on request.

Have we piqued your interest? Get in touch with us via the contact form, by phone, via email or via the product inquiry below!

Here you can easily ask a question or inquiry about our products:

Last update: 2024-26-06