Through effective cooling, the performance of optoelectronic components or measuring devices can be significantly increased, since, for example, the noise of image sensors can be lowered in this way. Our partner company IQ evolution is the specialist for the smallest customized components with an innovative 3D printing technology for metal heat sinks.

Their technique of »selective laser melting« allows for freedom in the design of effective cooling, which was not possible with conventional manufacturing processes (such as CNC milling).

On this page, we present examplary three solutions from IQ evolution for a wide range of electronics applications, which can be implemented similarly for projects in optoelectronics.

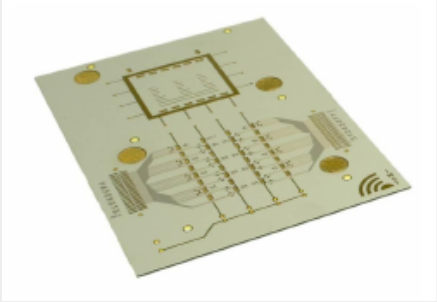

The continued increase in the packaging density of printed circuit boards calls for new ways regarding the heat management of electronic assemblies. One solution is a liquid cooler made using a metall 3D printer process and which is integrating directly into a multilayer board to effectively cool its components.

Details can be found in this PDF document.

A very effective way to dissipate the high heat flux densities of electronic power modules or power devices with high power density is the use of micro-coolers or micro-channel heat sinks made by SML. These active small cooling elements can transmit up to 1000 W/mm².

Beside a design for the often used TO-247 housings, all other housing types are available. Even customized designs in other shapes and thicknesses are possible.

Details can be found in this PDF document.

Dissipating the high heat flux densities of electronic power modules and power devices with high power density is often a very difficult task. New possibilities arise when during the design of a circuit an active water cooling is included directly. This example shows a DC/DC converter unit, which was developed as an application sample using 3D printed micro coolers.

Details can be found in this PDF document.

If we have aroused your interest, please contact us! We will gladly work out a concept for your specific application together with you.

Here you can easily ask a question or inquiry about our products:

Last update: 2019-11-07